Could My Food Cost Issue Be the Recipe Itself?

by John Laporte, President, RRFMG Technology Services

How To Manage Food Costs Effectively

Food cost management is one of the most critical aspects of running a successful restaurant, and discrepancies between theoretical and actual food costs can be a major red flag. When faced with a variance of over 5%, as seen in this scenario for a flagship steakhouse chain, it becomes necessary to dig deeper to identify and resolve the root cause.

In this case, the culprit was a seemingly straightforward issue—moisture loss in Prime Rib—yet its impact on food cost was significant. This article will explore how food cost issues can sometimes be traced back to the recipe itself and provide best practices for managing food costs effectively.

Understanding the Theoretical vs. Actual Food Cost Variance

Before we dive into the specific example of Prime Rib, let’s briefly discuss the difference between theoretical vs. actual food cost variance.

- Theoretical Food Cost: This is the ideal food cost, calculated based on the recipes, sales mix, and portion sizes of every menu item sold. It assumes perfect efficiency with no waste, shrinkage, or errors.

- Actual Food Cost: This is what you actually spend on food, derived from inventory usage and purchases.

When the variance between these two metrics exceeds acceptable thresholds—typically 2-3% for most restaurants—it’s a sign of inefficiencies, waste, theft, or procedural issues. For the steakhouse chain in this scenario, a 5% variance was alarming enough to warrant an in-depth investigation.

Uncovering the Problem: Prime Rib

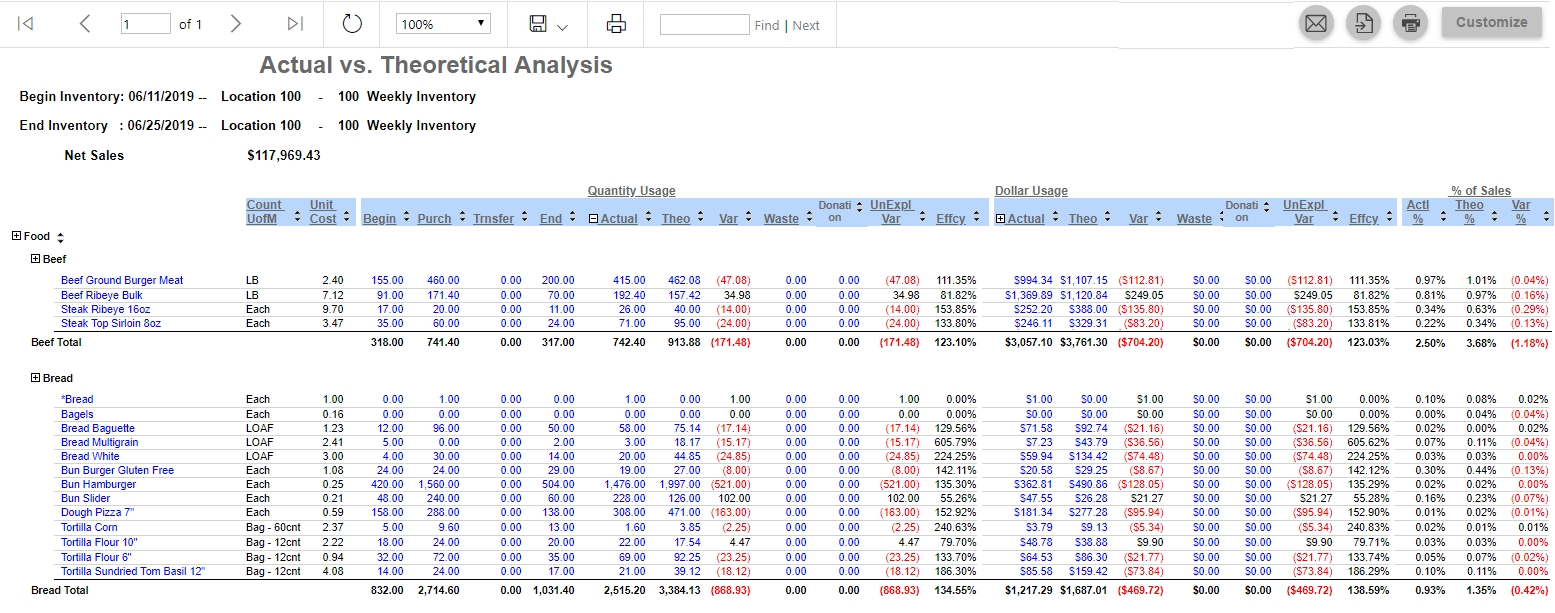

The issue arose from a new menu item: Prime Rib. Unlike most other items on the menu, the Prime Rib was purchased and sold by weight. This unique approach introduced challenges that weren’t immediately apparent. Using Restaurant365’s “Actual vs. Theoretical Analysis” report, the operations team pinpointed the Prime Rib as the source of inefficiency, with an alarming efficiency percentage of only 50%.

To uncover why, they conducted an end-to-end review of the in-store procedure for handling Prime Rib, from delivery to service. Here’s what they found:

- Receiving and Storage: The product was properly received and stored, so there were no issues with incorrect quantities or spoilage prior to preparation.

- Preparation and Cooking: The Prime Rib was being cooked and held in the oven until sold, which seemed efficient at first glance.

- Portioning and Serving: While portion weights were accurate at the time of service, the product was losing significant moisture and weight as it sat in the oven throughout the night.

This weight loss was directly responsible for the food cost issue. Each pound of Prime Rib purchased yielded far less than expected, throwing off the theoretical calculations.

Adjusting the Recipe to Account for Yield Loss

The operations team recognized that the recipe itself needed to be adjusted to address the yield loss. Yield, in this context, refers to the usable portion of the product after trimming, cooking, and serving. For high-moisture products like Prime Rib, it’s critical to account for cooking shrinkage—the percentage of weight lost during preparation.

Steps to Resolve the Issue:

- Measure Yield Loss: The team conducted tests to determine the exact percentage of weight lost during cooking and holding. This involved weighing the Prime Rib before and after cooking over several nights to identify consistent trends.

- Update the Recipe in Restaurant365: Once the average yield loss was calculated, they updated the recipe in the system to reflect the adjusted yield percentage. This ensured that theoretical food costs were based on realistic expectations.

- Train Staff: The team trained staff to better understand the importance of managing holding times and properly weighing portions to minimize additional waste.

- Optimize Holding Procedures: To further reduce weight loss, they experimented with techniques such as using a lower holding temperature or covering the Prime Rib to retain moisture.

- Monitor Results: After implementing these changes, they closely monitored food cost reports to ensure the variance fell back within acceptable ranges.

Lessons Learned: How Recipes Impact Food Costs

This scenario highlights an often-overlooked truth: recipes are living documents. They must be regularly reviewed and adjusted to account for changes in product specifications, preparation methods, or serving practices. Below are some best practices to ensure your recipes support accurate food cost management:

1. Account for Yield in All Recipes

Every ingredient has a yield percentage, which should be factored into recipes. For example:

- Proteins like Prime Rib lose weight during cooking.

- Produce may require peeling or trimming.

- Certain items, like sauces, may experience evaporation or separation.

2. Use Accurate Portioning Tools

Consistently using calibrated scales and portioning tools ensures that serving sizes match the recipe. Over-portioning, even by small amounts, can lead to significant cost increases over time.

3. Train Your Team

Staff must understand the role recipes play in controlling food costs. Regular training on portioning, preparation techniques, and waste reduction can prevent procedural errors.

4. Leverage Technology

Restaurant management platforms like Restaurant365 provide powerful tools for tracking and analyzing food costs. Use features like recipe costing and inventory tracking to identify discrepancies and adjust as needed.

5. Monitor High-Cost Items Closely

High-cost items, like Prime Rib, are more sensitive to inefficiencies. Regularly review their performance and make adjustments quickly when issues arise.

6. Test Recipes Periodically

Conduct regular tests to verify that recipe yields and theoretical costs align with real-world results. This is especially important for new menu items or seasonal changes in sourcing.

Beyond the Recipe: Holistic Food Cost Management

While recipes play a critical role in food cost accuracy, other factors must also be considered to achieve optimal results:

- Inventory Management: Ensure counts are accurate, and review waste logs to identify recurring issues.

- Supplier Relationships: Verify that products meet the agreed-upon quality and weight specifications.

- Menu Engineering: Analyze the profitability of each menu item and adjust pricing or ingredients as needed.

- Waste Reduction: Track and address sources of food waste, whether they occur during preparation, service, or spoilage.

Conclusion

Managing food costs is a complex but vital part of running a successful restaurant. As this scenario illustrates, even small details—like unaccounted-for yield loss in a recipe—can have a big impact on profitability. By leveraging tools like Restaurant365, staying vigilant in monitoring procedures, and maintaining accurate recipes, restaurant operators can keep food cost variances under control and protect their bottom line.

When faced with a food cost issue, don’t overlook the possibility that the recipe itself may need adjustment. With a systematic approach, the right tools, and a commitment to best practices, you can turn food cost challenges into opportunities for improvement.

For more information, please fill out the form below. We’ll circle back with you shortly to discuss your requirements in further detail.

We’d love to Meet You In Person Or Via The Web!

If you have any questions, or just want to learn more about how our services can contribute to your operation’s success, please fill out the form and we’ll respond as soon as we can. Alternatively, call us directly at (818) 888-9579.